COMPANY NEWS

Denizli Kaya Tekstil: Global Knitting Leader

Producing all kinds of circular knitting, warp knitted fabrics and round knitted fabrics, Denizli Kaya Tekstil, a leader in the...

Cottonbox Expands Globally

Sümaş Tekstil produces and sells cotton home textiles with the brand, Cottonbox. They have been selling their products labelled with...

Beğenal Targets Global Recognition

Producing at top standards in its 2,500 sqm facility in the city of Denizli, Beğenal Home Textile works to provide...

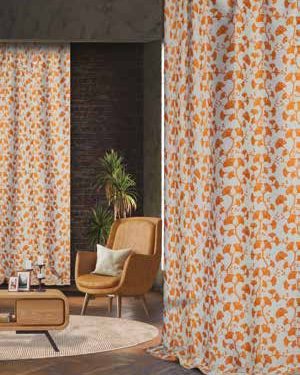

Maslina Textile: Global Sustainable Curtains

As one of the suppliers of the best curtains,Maslina Textile has been working to be oneof the sustainable leading companies....

Intertextile Shanghai: 30 Years, 900 Exhibitors

SHANGHAI – Intertextile Shanghai Home Textiles, Asia’s premier home textiles trade fair, is set to welcome global buyers from August...

HOMETEX 2024: Istanbul’s Top Textile Fair

Organised by Turkish Home Textile Industrialists’ and Business People’s Association (TETSIAD), the umbrella or- ganisation of the home textile industry,...

Nisa Textile: Sierra Linens Excellence

Nisa Textile is one of the leading companies operating in the home textile industry in Turkiye with its lovely products...

Enas Brand: 2024 Curtain Trends

Köseoğlu family, which has 35 years of ex- perience in the sector, first introduced Elizabeth and then Enas brands to...

Onur Home Collection: Denizli’s Global Textile Success

Onur Home Collection, a Denizli-based company that produces mostly towels and bathrobes in Denizli, exports its competitive goods to 40...

Zeyd Tekstil: Global Comfort & Innovation

The textile journey of Zeyd Tekstil company started in the 90s, when it was established by using the knowledge and...