-

TENCEL™ Lyocell fibers with REFIBRA™ Technology can now feature up to 30% of pulp made from upcycled cotton scraps collected from garment manufacturing process.

-

Lenzing’s family of TENCEL™ Lyocell fibers with REFIBRA™ Technology can now help to provide even more sustainable fiber options for knits, denim, towels and bed linen.

Frankfurt/Lenzing – Lenzing Group (Lenzing) announced a new milestone for its pioneering REFIBRA™ technology with an increase of up to 30% in recycled raw materials usage to further drive circular economy in the textile segment. The new offering is now available in the family of TENCEL™ Lyocell fibers with low fibrillation properties.

Frankfurt/Lenzing – Lenzing Group (Lenzing) announced a new milestone for its pioneering REFIBRA™ technology with an increase of up to 30% in recycled raw materials usage to further drive circular economy in the textile segment. The new offering is now available in the family of TENCEL™ Lyocell fibers with low fibrillation properties.

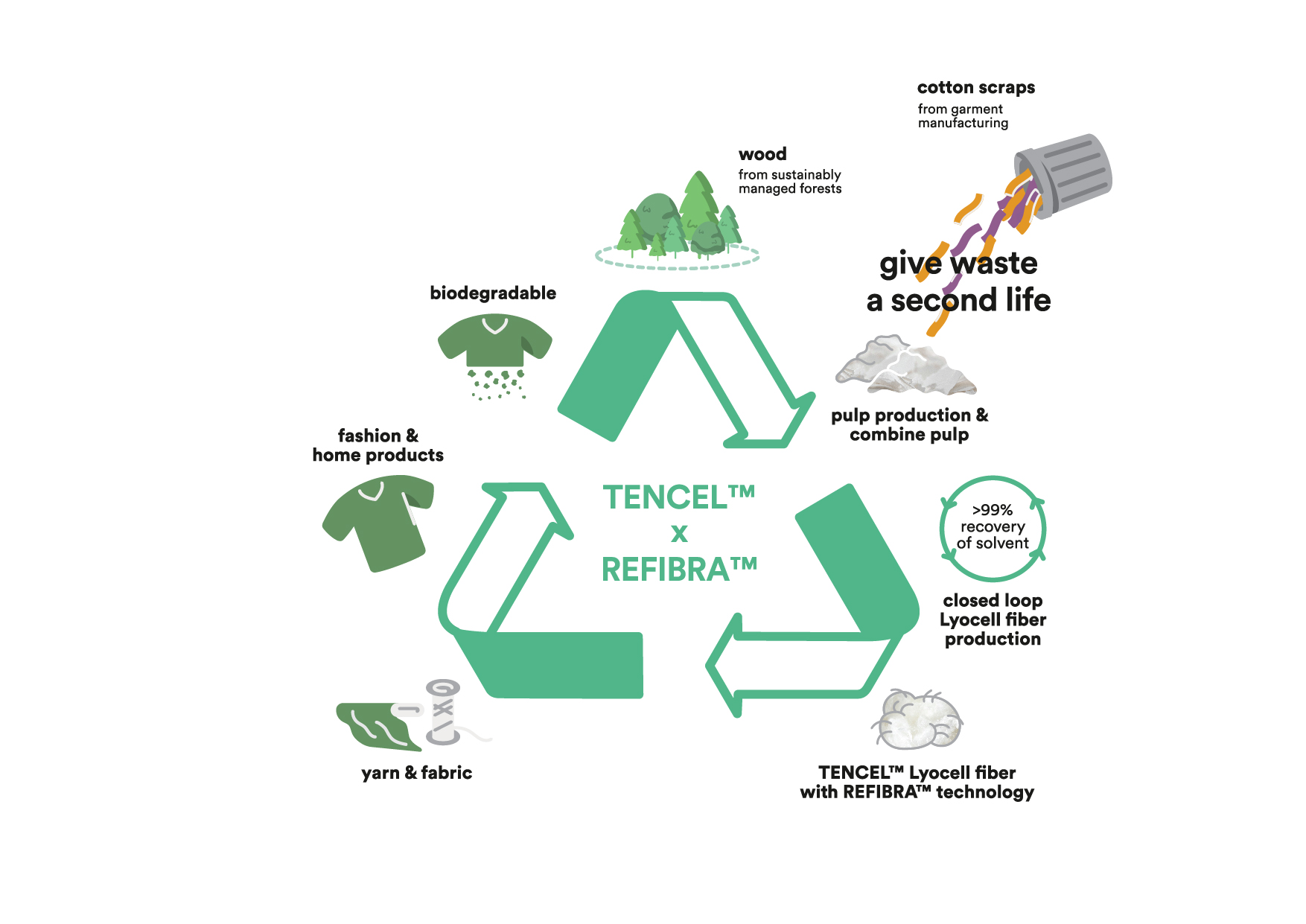

Produced in eco-responsible closed-loop production process, the new fibers are 100% biobased, and are produced of wood pulp from sustainably managed forests and an increase of up to 30% of pulp made from upcycled cotton scraps collected from garment manufacturing process. In addition to having low fibrillation and moisture management properties, the fibers also feature enhanced breathability, along with silky smoothness and strength. With the new fiber type, the portfolio of TENCEL™ Lyocell fibers with REFIBRA™ Technology will be expanded to become the ecologically responsible alternative for knitwear, lingerie and towels, in addition to current applications in denim, athleisure wear, apparel and home textiles.

“Over the years, we have witnessed a rise in the global demand for more sustainable materials among fashion and home product brands and consumers. Through raising recycled raw material usage to up to 30% in our pioneering REFIBRA™ Technology, we are not only addressing this inevitable trend, but also providing more nature-friendly fiber offerings to brands and consumers as a testament to our commitment to protecting the environment. The higher composition of upcycled cotton in the production of our fibers powered by REFIBRA™ technology gives cotton scraps a second chance and allow apparel or home textile products to be more sustainable. Coupled with a new identification system that allows fibers powered by REFIBRA™ technology to be identified in clothing and textile products, we can provide full transparency of the supply chain for brands and consumers, giving them a seal of confidence that the products are made of sustainable fibers. Moving forward, we will continue to up the game for the innovation of sustainable fibers and pave the way for circular economy in the textile industry ecosystem,” said Florian Heubrandner, Vice President of Global Business Management Textiles of Lenzing.

With low fibrillation properties, the new fibers are proven to remain smooth and gentle on skin after repeated wash. Like other TENCEL™ Lyocell fibers with REFIBRA™ Technology, the fibers divert tons of cotton scraps from entering landfills or incineration by blending up to 30% of pulp made from upcycled cotton scraps collected from garment manufacturing process. The biobased fibers are also produced with high resource efficiency and low environmental impact, reusing water and solvent at a recovery rate of more than 99.5 %.

With low fibrillation properties, the new fibers are proven to remain smooth and gentle on skin after repeated wash. Like other TENCEL™ Lyocell fibers with REFIBRA™ Technology, the fibers divert tons of cotton scraps from entering landfills or incineration by blending up to 30% of pulp made from upcycled cotton scraps collected from garment manufacturing process. The biobased fibers are also produced with high resource efficiency and low environmental impact, reusing water and solvent at a recovery rate of more than 99.5 %.

Moreover, with an innovative special identification technology designed to confirm fiber origin, TENCEL™ Lyocell fibers with REFIBRA™ Technology are identifiable in yarns, fabrics and final garments. This does not only improve supply chain transparency, but also gives fashion brands a seal of confidence that the fibers of their apparel or home textile products are sustainably sourced and produced.

#Lenzing REFIBRA, #raw material, #TENCEL, #Lyocell fibers , #Frankfurt, #technology, #process,